| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : ZUN HUANG

Model Number : ZH-100HL

Certification : CE ISO9001

Place of Origin : CHINA

MOQ : 1 unit

Price : Negotiation

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 20 units/per month

Delivery Time : 20-35days

Packaging Details : Steel frame or wooden case

Material : SUS304 SUS316

Function : Beer Brewing Equipment

Application : Brewpub, Restaurant, home

Thickness : Inside:3mm Outside:2mm

Insulation : Polyurethane(PU):80mm

Cooling Method : Dimple cooling jacket

Inner surface : Pickled and passivated

Conical : 60 or 78 degree

100HL Conical Fermenter Stainless Steel Brewing Unitank

for Craft Beer Fermenting System

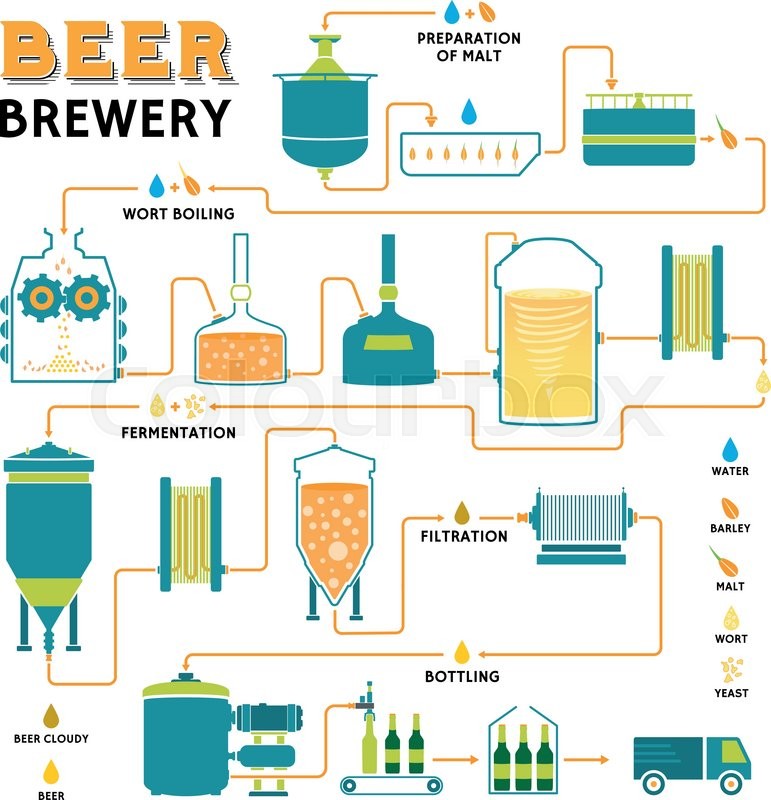

Craft beer brewing process:

1. Malt ,water, hops ,yeast.

Beer Brewing Equipment List

| 1 | malt milling system | malt miller machine grist case |

| 2 | Mash system | Mash tank/Boiling tank lauter tank Whirlpool tank |

| 3 | Fermenting system | Beer fermenters Bright beer tanks Yeast adding tank Accessories, such as sample valve, pressure gauge, safety valve and so on |

| 4 | Cooling system | Ice water tank Refrigerating unit Ice water pump |

| 5 | CIP cleaning system | disinfection tank & alkali tank &cleaning pump etc. |

| 6 | Controller | Control system, we have PLC automatic and semi-automatic, the elements brand include LG, Siemens and so on. |

| 7 | Keg filling system | Keg filling system ( keg washer and keg filler machine), the control system brand is Siemens. |

Fermentation Tank

1. Cylinder tank; Inside surface: SUS304, Thickness: 3mm,Outside surface: polishing stainless steel, Thickness: 2mm

2. Thermal insulation material: Polyurethane (PU) foam, Insulation thickness: 80MM.

3.Inside surface is pickled and passivated to resist corrosion.

4.Manhole: side manhole

5.Design pressure 3bar, Working pressure: 1.5bar

6.Bottom design: 60 Or 78 degree cone for easy to exist yeast.

7.Cooling method: Dimple cooling jacket.

8.Cleaning system: Fixed-round rotary cleaning ball.

9.Control system: PT100, temperature control

10. Hops adding device, CIP arm with spray ball, pressure gauge, mechanical pressure regulating valve, sampling valve, breath valve, Ice water solenoid valve, safety valve, etc.

Company Information:

Shandong Zunhuang Brewing Equipment Co., Ltd is the domestic integrated industrial and trade comprehensive enterprise dedicated in research, manufacturer, development, sales and after-sale service, until now have the 16 years produce experience, company focuses on beer system project that refer to fruit wine equipment, white spirit and alcohol equipment etc, our company purpose: “Quality first, customer highest”, use the short period provide direct and comprehensive service, and improve the products’ value and market competitive.

Ten provide to service you:

1. After-sale Service for the whole life.

2. 24h service for you, solve your urgent problem first time.

3. 3 years warranty for the main products.

4. Free design for your brewery layout for 2D or 3D.

5. Spare parts replacement and repair service provided.

6. Engineer going abroad for installation, debugging and technical training if you need.

7. Provide the Form E, CO, etc..others necessary reduce import Tax files for you.

8. To provide update information about brewing equipment technology once we test.

9. Help you send the goods if you have others company order, then send to you together.

10. Door to Door service, if you need any brewing parts.

Our certification:

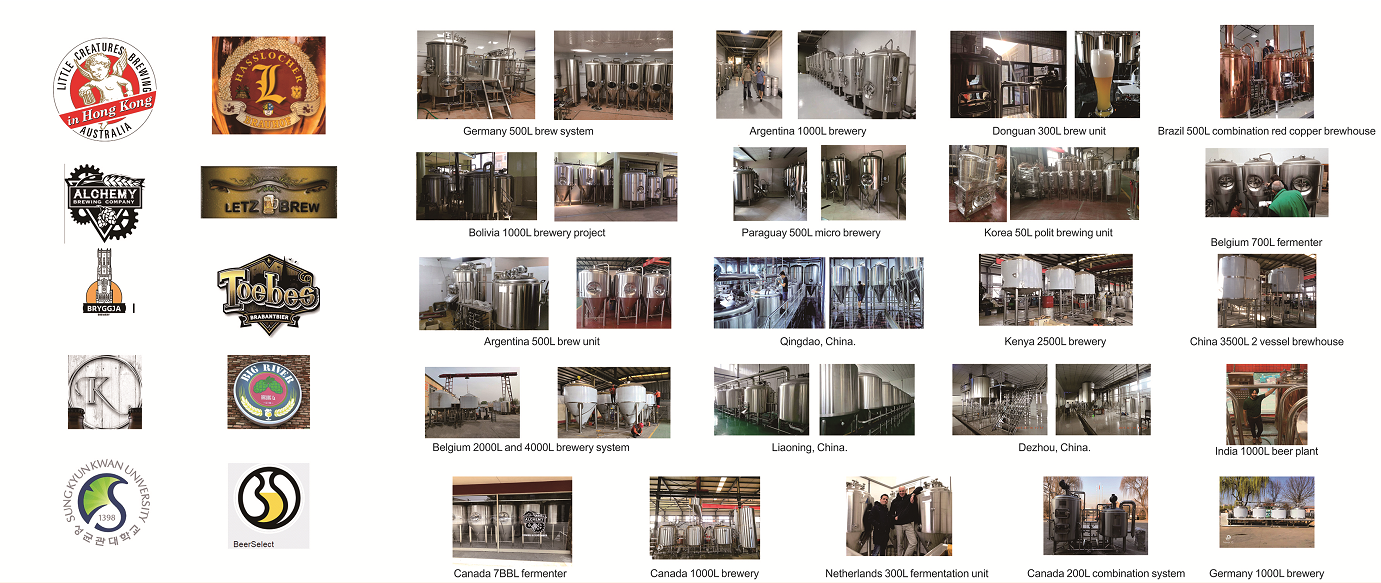

Zunhuang technology has been internationally recognized, and achieved ISO9001: 2008 international quality system certification, import and export EU CE Certification; accepted ASME, CE, AS1210 third-party inspection, with import and export rights, the company's products have been in over 60 countries worldwide.

Packing and shipping

1. Ocean shipment,railway shipment,express delivery.

2. No matter flat pack to save shipping cost,or fill with your merchandise into allassembled displays to ship together,all is up to you.

3. And we have our own department to arange the shipments.we ship worldwide dierctly by see,railway or express.we will provide all documents you need to import.

4. We packed the goods to meet the transport distance, shock, rust and anti-handling requirements damaged before shipping, to ensure the safe transport of goods to reach the buyer designated location before it is shipped.

Exhibition:

Customer Case:

Welcome to talk more details with us,we'll reply you promptly.Cheers!

|

|

100HL Conical Fermenter Stainless Steel Brewing Unitank Images |